In the civil engineering industry, structural challenges call for innovative solutions that push the boundaries of feasibility. The designers and engineers of Taipei 101 creatively overcame obstacles such as earthquakes, typhoons, poor soil and a high water table. In this case study, we explore how innovations like a pendulum tuned mass damper and a unique outrigger truss were used to create a globally recognized iconic structure.

What is Taipei 101

Taipei 101, located in Taipei, Taiwan, held the record for the tallest building in the world from 2004 to 2010. Designed by C.Y. Lee & Partners and built by KTRT Joint Venture, this mega structure stands 508 meters tall with 101 floors and 5 basement levels. The exterior features glass windows and aluminum panels, arranged in a hexagonal pattern. The interior is divided into eight zones, with eight symbolizing wealth in some Asian cultures. The first five floors are retail and commercial spaces, the next 91 floors are office spaces, and the top four levels house a public observatory. The architects were inspired by the joints of indigenous bamboo and the tiers of pagodas, each zone with a narrower base and a wider top resembling a flower opening up to the sky.

Taipei 101 has received numerous awards for its energy-efficient design including the LEED Platinum certification and ISO 14001 certification. Energy-efficient technologies help reduce the building’s energy consumption by up to 30% when compared to traditional buildings. Some of these efforts include double-paned windows that insulate the building and reduce heat gain, energy saving LED lighting, regenerative elevators that generate electricity as they descend, and a solar power system. Taipei 101’s efficient water conservation practices such as using a rainwater harvesting system, low-flow water fixtures, Xeriscaping, and a greywater treatment plant help reduce water consumption by up to 30%, contributing to the building’s overall sustainability.

When beginning this massive project, the location posed significant challenges. Taiwan is located on the Ring of Fire, a path along the Pacific Ocean with Earth’s highest concentration of volcanoes and earthquakes. Additionally, being an island, Taiwan is susceptible to typhoons and high winds. The developers needed solutions to these challenges to build this massive structure. Consequently, Taipei 101 became the first skyscraper to use a pendulum as a structural tuned mass damper, supported by a unique outrigger truss system.

Tuned Mass Damper

Damper systems enhance structural stability. In Taipei 101, a 726-ton yellow orb oscillates to counteract winds and earthquakes. The mass, equal to 0.24 percent of the total building mass, is located with its equator 1 meter above the 88th floor. The pendulum is aided by shock absorbers that convert motion to heat by forcing fluid through small internal openings. The tuned mass damper uses sensors to detect building movement and engineers fine-tune the shock absorbers to match the measured behavior of the swing by tightening or loosening attached cables and strings. The orb can oscillate up to 1.5 meters in any direction reducing the skyscraper’s sway by 30-40%. On September 18th, 2022, a 6.8 magnitude earthquake struck the skyscraper. The tuned mass damper proved to be very successful in mitigating the effects of wind and sway on the building.

Outrigger Truss

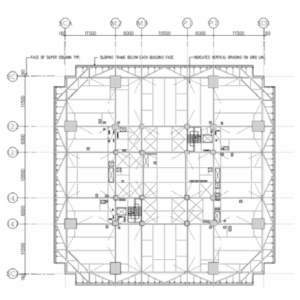

In addition to the tuned mass damper, Taipei 101 features strong outrigger trusses on mechanical floors. These trusses connect the outer and inner columns to enhance wind and earthquake resistance. The core center is complemented by perimeter columns connected by outrigger trusses, allowing for weight distribution between the columns in tension and compression.

Furthermore, belt trusses distribute tensile and compressive forces to the exterior frame columns. Below level 27, these trusses are two stories deep, located on floors nine, nineteen, and twenty-seven. Above the 27th floor, single-story belt trusses installed every eight floors tie the main perimeter columns with cross-bracing. This configuration helps transfer weight to the core columns. At the base, 1.2-meter-thick slurry walls extend up to 47 meters below the ground, surrounding the tower. The slurry walls were necessary to overcome the soft soil and high water table of the construction site. These features help ensure the stability and safety of the skyscraper.

Broader Impact

Taipei 101 stands as a testament to the ingenuity and resilience of modern engineering. By integrating advanced technologies such as the tuned mass damper and outrigger trusses, the designers and engineers successfully addressed the unique challenges posed by the building’s location. Since its constructions, Taipei 101 has inspired and set standards for large skyscraper developments in the field of civil engineering such as the Tokyo Skytree and buildings at Sabiha Gökçen International Airport in Turkey. This iconic skyscraper not only exemplifies architectural and engineering excellence but also highlights the importance of innovative solutions in overcoming natural disasters.

By Aquinas Engineering