Ever wonder how one of the world’s most famous architectural mistakes became an engineering marvel? The Leaning Tower of Pisa is now deemed safe and visited by millions of tourists annually. What began as a construction error has evolved to an iconic example of architecture and engineering ingenuity. This article delves into the origins of the tower’s lean, and the measures taken to stabilize it.

The Initial Lean: Foundations Built on Unstable Ground

In 1173, construction began on what would become Pisa’s most iconic piece of architecture. Pisa, derived from the Greek word for ‘marsh land’, is situated on ground composed of a dense mixture of clay, sand, and minerals. The composition of the ground resulted in an uneven surface, challenging the construction of large and heavy structures. Before the Tower of Pisa, there had been no other structures in the city that surpassed a certain weight and visibly showed signs of sinking. The initial engineers constructed a small foundation adhering to the standard practices of the time. Before this period, only the Ancient Romans were known to counteract unstable ground with massive stone pillar piles that would rest on the Earth’s bedrock. Therefore, the tower was predisposed to structural issues from its foundation. Construction was interrupted by the war between Pisa and Genoa, allowing the foundation of the then four-story tower to settle more deeply into the ground than it would have with continuous construction. Following the war, around the year 1272, engineer Giovanni di Simone observed a slight lean in the tower. To compensate, he built the next three stories with slightly taller pillars on the sinking side. By 1370, the tower was completed with a total of seven stories and a bell chamber, all tilting at 1.6 degrees. However, the lean continued to increase.

Early Stabilization Attempts: A Series of Missteps

In the ensuing centuries, numerous attempts were made to correct the tower’s tilt and prevent its collapse. Estimates indicated the tower was falling at a rate of 0.05 inches per year. In 1838, a concrete walkway known as the Catino was constructed around the base to inspect the sunken foundation. This Catino failed to improve the tower’s inclination as it removed supporting sand. In fact, it caused more harm than good for future stabilization efforts. In 1935, Benito Mussolini, the infamous fascist prime minister of Italy, directed engineers to attempt a different method to correct the lean. He suggested injecting mortar into the ground on the leaning side of the tower to reinforce the base. However, the uneven distribution of the mortar rendered the attempt ineffective. These failed attempts exacerbated the tower’s sinking. Engineers needed to identify the definitive cause of the tilt to devise a plan to halt its progression: the soil.

By the 1970s, technological advancements had significantly progressed. Computers were employed to calculate the Tower of Pisa’s center of gravity which is essential in understanding the overall stability margin. This required computerized calculations due to the building’s asymmetry; the floors above the fourth floor were constructed with additional masonry on one side to counteract the lean. The center of gravity was found to be around the fourth floor, and this information was used to calculate when the tower could collapse. If the tangent line from the center of gravity extended beyond the floor’s circumference, the tower would collapse. Engineers determined the critical tilt angle of collapse was 5.44 degrees. Thus, engineers installed a modern monitoring system to track inclination along with surveying benchmarks. Advanced technology was utilized to model the soil stiffness around the tower, calculate the lean’s trajectory and the exact amount of soil needed to be excavated to avoid collapse. Based on these calculations, engineers added 600 tons of lead ingots to the base on the side opposite the lean. Additionally, engineers anchored the tower with individually adjustable steel cables for added security. These measures corrected the lean by 0.01 degrees. Despite the slight correction, the tower’s appearance was marred by the presence of 600 tons of lead on one side. Engineers aimed to straighten the tower while preserving its iconic lean. Compounding the urgency, a similar leaning tower in Pavia collapsed in 1989, intensifying the need to rectify Pisa’s lean.

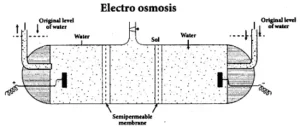

In 1990, the Italian government enlisted leading engineers to prevent the tower’s collapse. Multiple solutions were proposed to achieve this goal. One proposition involved replacing the lead ingot with ten deep anchors to pull the northern side of the tower. This initial attempt was unsuccessful for several reasons. Upon initial excavation, engineers discovered that the concrete walkway, or Catino, was not separate but supported the tower. Continuing this proposal would require the removal of portions of the walkway. However, when a section of the Catino was removed, the tower began to tilt again. The effort was abandoned, the Catino was reinstalled, and 350 additional tons of lead were added to rectify the initial potentially disastrous effort. A subsequent proposal suggested pumping out groundwater from the north side of the tower to level out the ground. Engineers were uncertain about the long-term consequences of this action, fearing that reducing groundwater levels could have adverse effects. As a result, this proposition was not pursued. A more technologically advanced idea involved electroosmosis, which entails moving water through the soil using an electric field. This method would involve placing two in ground electrodes, one on either side of the tower, and charging them electronically. Since clay particles have a negative surface charge, the electrodes would attract the positively charged water particles to one side of the tower, where they can be pumped to the surface. A large-scale field test was conducted near the tower. However, it was unsuccessful due to the over conductivity of the soil. Once again, Pisa’s soil contributed to the tower’s issues.

The Modern Solution: Engineering Meets Innovation

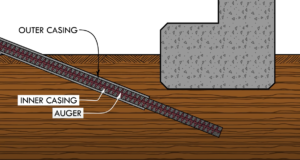

Finally, in 1999, a solution involving excavation was found to be effective. The proposition included a design for diagonal tunnels drilled beneath the surface and under the tower. The idea was to gradually remove soil from beneath the north side of the tower to level the building. The drill was designed as a hollow stem auger within two casings: one stationary outer casing and an inner casing. They were pushed below the building’s footing, with guide tubes ensuring the drilling remained on course. They started with a preliminary trial of 12 holes, which proved successful. After several months of this preliminary stage, the tilt was corrected by approximately 0.04 degrees giving the engineers the confidence to proceed, ultimately drilling a total of 41 holes by the year 2000. In total, 38 cubic meters of soil were removed. Engineers removed the lead counterweights and installed a water drainage system to manage fluctuating groundwater levels. The tower was also structurally attached to the Catino, increasing the effective size of the foundation. Following the successful stabilization project, the tower’s tilt was corrected by 0.5 degrees, and it now leans at 4 degrees from perpendicular. Reopened to the public in the year 2001, engineers estimate that the tower will remain stable for at least another 300 years.

Lessons for Structural Engineers: What We Can Take from Pisa’s Lean

The stabilization of the Leaning Tower of Pisa offers valuable insights for today’s structural engineers:

- Understanding Soil-Structure Interaction: Pisa’s iconic lean underscores the impact of soil composition and behavior on structural integrity, highlighting the importance of pre-construction soil analysis and considering ground conditions in design.

- Monitoring and Real-Time Data: The role of continual monitoring in Pisa’s stabilization, through technology that calculated precise tilt thresholds, is applicable in modern projects. Advanced sensors and real-time data can mitigate the risk of structural shifts in challenging environments.

- Adaptability in Engineering: The iterative design adjustments made by Pisa’s engineers reveal the importance of responsive engineering practices. Embracing adaptable methods helps modern engineers address foundation issues and adjust for unforeseen changes mid-project.

The Leaning Tower and Beyond: A Comparative Look at Modern Challenges

The Leaning Tower of Pisa stands today not only as a testament to historical architectural ambition but also as a symbol of modern engineering ingenuity. The meticulous efforts to stabilize the tower, from the initial missteps to the eventual success, highlight the critical role of understanding and adapting to geological challenges. This journey of the Tower of Pisa mirrors the ongoing saga of the Millennium Tower in San Francisco, where engineers are grappling with similar issues of foundation instability due to soil conditions. The Millennium Tower, much like its Italian counterpart, has faced significant tilting due to soil conditions, prompting innovative solutions to halt its lean and ensure its safety. For civil engineers, these stories serve as powerful reminders of the importance of continuous learning and adaptation in the face of complex engineering challenges. As we look to the future, let the lessons from these iconic structures inspire us to push the boundaries of what is possible. Whether it’s through advanced monitoring systems, innovative foundation techniques, or collaborative problem-solving, the field of civil engineering holds the key to preserving our architectural heritage and building a resilient future.

As civil engineers, we’re constantly facing new foundation and soil-related challenges. Have you encountered similar issues with soil instability or load balance in your projects? Let us know on our website or our social media platforms.

By Aquinas Engineering