Concrete is one of the most essential and widely used materials in civil engineering and construction, globally exceeding 12 billion tons annually on a global scale. However, concrete is not without its flaws. Inevitably, cracks can compromise the integrity of concrete structures. Various types of cracks, including settlement, expansion, plastic shrinkage, shear, and flexural cracks, can occur due to factors such as reinforcement corrosion, weathering, thermal stresses, design flaws, improper mixing, vibration and curing, heavy loads, poor-quality materials, or excessive water. Additionally, concrete production significantly contributes to global CO2 emissions, accounting for approximately 7% of total emissions (Habert et al.). Engineers have sought alternatives that can recover from cracks and offer more sustainable qualities, leading to one possible conclusion: self-healing concrete.

The concept of self-healing is inspired by natural processes. Plants regrow stems, starfish regenerate limbs, and the human body forms scabs and heals bones after fractures. In ancient Rome, self-healing materials were used in architecture, such as the Pantheon. Regional resources led to the formation of a unique stone made from volcanic ash and quicklime. When this compound came into contact with water, cracks would begin to recrystallize. These natural examples inspired scientists to develop self-healing concrete, which is increasingly used in the civil engineering industry. Self-healing concrete has potential applications in various areas, including roadways and pavements, tunnels and sea defense walls, residential buildings, large infrastructure projects, and dams and reservoirs. Self-healing concrete can be particularly beneficial for bridges, where fissures and freeze-thaw cycles pose challenges to concrete longevity.

Autogenous Healing Method

Further education is necessary to practically apply this innovative product. There are two primary methods for self-healing concrete: autogenous healing and autonomous healing. Autogenous healing refers to concrete’s natural ability to heal small cracks through the continued hydration of unreacted cement particles and the carbonation of calcium hydroxide. Water facilitates the covering of small cracks by cement particles. However, this method requires a consistent presence of water and is limited to curing small cracks.

Autonomous Healing Methods

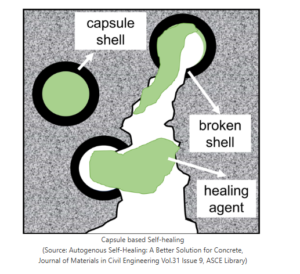

Leading industry investigations favor advancing the autonomous healing method for concrete. This method involves incorporating additional materials or systems into the concrete to facilitate self-repair. One option is the capsule-based healing method, where cylindrical or spherical capsules containing healing agents are embedded in the concrete. The capsule shells can be made of silica, ceramics, glass, polystyrene, or urea-formaldehyde. When cracks form, the capsule shells break open, releasing the healing agents to seal the cracks. These agents can include epoxy resins, polyurethane, or methyl methacrylate monomers (MMA).

Another autonomous option for self-healing concrete involves vascular systems. These systems consist of a network of hollow tubes filled with healing agents embedded in the concrete. Preferably, Inorganic Phosphate Cement (IPC) is used with clay tubes in this method. When cracks occur in the IPC, the healing agents flow through the tubes to the damaged area. The flow of the healing agents is driven by hydrostatic pressure or gravitational forces.

Embedding Shape Memory Alloys (SMAs) is another method for self-healing concrete. SMAs are smart materials made of embedded wires that remember the original shape of the concrete, even after deformation, helping it to self-center. Research shows that sending an electrical current through SMAs can effectively repair and close small cracks. This solution is suitable for retrofitting existing concrete structures.

Microbial Healing

Microbial healing is another approach considered for self-healing concrete. This environmentally friendly and cost-effective method involves adding bacteria that produce limestone to the concrete. When the concrete cracks, the bacteria germinate, breaking spores and ingesting calcium lactate to create limestone. Chemically, calcium carbonate (CaCO3) precipitation helps repair micro-cracks in concrete. Microbial spores and calcium nutrients containing healing agents are produced in batches and then incorporated into the concrete. Researchers have conducted trials on the cracks in the side walls of ships, yielding positive results within a 60-day timeframe. The chemical reaction is illustrated in the image below.

A research paper titled “Large Scale Application of Self-Healing Concrete: Design, Construction, and Testing” (Davies, Robert et al.) concludes that the optimal bacterium for self-healing concrete is Bacillius Subtilis or BKH2. The researchers observed that this bacterium is ideal for self-healing concrete, providing a user-friendly interface. In addition to being stable and thriving in alkaline conditions, the bacteria aid in repairing cracks in concrete by producing calcium carbonate crystals. The bacteria help reduce the pH levels of the concrete when cracks begin to form. The investigation found the bacteria were most effective when applied directly during the mixing process along with a calcium nutrient.

Applications and Benefits

Self-healing concrete offers several advantages, including increased longevity, enhanced strength, and reduced lifetime maintenance requirements by up to 50%. These benefits make it an attractive option for a wide range of construction projects. However, there are also some drawbacks to consider. The cost of self-healing concrete can be higher compared to traditional concrete, and there is a lack of widespread industry knowledge about its use. Additionally, the absence of standardized codes for self-healing concrete can pose challenges for its implementation. Despite these challenges, a lifeguard station in the Netherlands has successfully utilized self-healing concrete. Constructed from self-healing concrete in 2011, (CMQuebral Consulting Ltd. “The First-Ever…) it was a finalist for the European Inventors Award in 2015, potentially sparking a revolution in building construction (EPO). Self-healing concrete has also been successfully applied to large-scale projects, such as the Mihara Bridge in Japan, where it demonstrated a 40% reduction in material usage and enhanced structural resilience (Li, Hui et al., 2017).

Call To Action

Self-healing concrete represents a groundbreaking advancement in the field of civil engineering, offering a promising solution to the persistent issue of concrete degradation. By mimicking natural healing processes, this innovative material not only enhances the durability and longevity of concrete structures but also contributes to sustainability by reducing maintenance costs and lowering CO2 emissions. While challenges such as higher costs and the need for further industry education remain, the potential benefits of self-healing concrete make it a compelling choice for future infrastructure projects. As research and development continue to advance, self-healing concrete could become a standard in construction, paving the way for more resilient and sustainable infrastructure worldwide.

Many will say that self-healing concrete is unaffordable at its current state. But can we afford to overlook a material that not only repairs itself but also reduces environmental impact? The choice is ours to make. Let us know how you are reducing your environmental impact on our website or our social media platforms.

By Aquinas Engineering

Sources

Achar, Apoorva H P. “Self Healing Concrete: The Future of Sustainable Construction.” Brick&Bolt, 18 Oct. 2024, https://www.bricknbolt.com/blogs-and-articles/construction-guide/self-healing-concrete.

CMQuebral Consulting Ltd. “Self-Healing Concrete.” CMQ Consulting, 8 Jan. 2021, https://cmqconsulting.com/self-healing-concrete/.

CMQuebral Consulting Ltd. “The First-Ever Building That Used Healing Concrete.” CMQ Consulting, 29 Jan. 2021, https://cmqconsulting.com/the-first-ever-building-that-used-self-healing-concrete/.

Davies, Robert, et al. “Large Scale Application of Self-Healing Concrete: Design, Construction, and Testing.” Frontiers in Materials, vol. 5, 3 Sept. 2018, https://www.frontiersin.org/journals/materials/articles/10.3389/fmats.2018.00051/full.

European Patent Office. “Hendrick Marius Jonkers | Self-Healing Concrete Containing Bacteria.” European Patent Office, 2015, https://www.epo.org/en/news-events/european-inventor-award/meet-the-finalists/hendrik-marius-jonkers.

Habert, G., et al. “Environmental Impacts and Decarbonization Strategies in the Cement and Concrete Industries.” Nature Reviews Earth & Environment, vol. 1, 22 Sept. 2020, https://www.nature.com/articles/s43017-020-0093-3.

Li, Hui, et al. “Analyzing Virtual Water Pollution Transfer Embodied in Economic Activities Based on Gray Water Footprint: A Case Study.” Journal of Cleaner Production, vol. 162, 10 Sept. 2017, https://www.sciencedirect.com/science/article/abs/pii/S0959652617310983?via%3Dihub.

Matchar, Emily. “With This Self-Healing Concrete, Buildings Repair Themselves.” Smithsonian Magazine, 5 June 2015, https://www.smithsonianmag.com/innovation/with-this-self-healing-concrete-buildings-repair-themselves-180955474/.

Pollock, Aaliyah. “Building a Sustainable Future: The Incredible Potential of Self-Healing Concrete.” RICS, 25 Jan. 2024, https://www.rics.org/news-insights/building-a-sustainable-future-the-incredible-potential-of-self-healing-concrete.

Venugopal, Anagha. “Self-Healing Concrete | How Self Healing Concrete Works.” Engineering Civil, 30 Sept. 2020, https://engineeringcivil.org/articles/concrete/self-healing-concrete-how-self-healing-concrete-works/.