Modular construction – the assembly of prefabricated building modules manufactured offsite – is rapidly emerging as a transformative approach in the U.S. building industry. What was once a niche method is now gaining mainstream traction, offering promises of faster project delivery, improved quality, and solutions to labor shortages. In fact, the market share of modular construction in new U.S. projects has surged in recent years, rising from about 2% of new construction starts in 2015 to over 6.6% by 2023. The total value of modular projects in North America exceeded $14.6 billion in 2023, and forecasts predict continued growth – the U.S. modular market is expected to reach nearly $19 billion by 2030, with roughly 7–8% annual growth. This trend underscores a simple truth: offsite construction is no longer the future – it’s the present, and it’s accelerating.

But as modular methods move beyond the blueprint and into reality, structural engineers are at the forefront of addressing the unique challenges that come with this construction paradigm. From ensuring robust prefab structure connection details to navigating evolving modular building code requirements, engineers must blend creativity with rigor. This article explores the structural engineering considerations critical to offsite and prefabricated construction – covering industry growth, design challenges and solutions, material choices, module integration, DfMA strategies, logistics of transport and assembly, and the codes and standards governing modular projects.

A Growing Trend: Modular and Prefabricated Construction on the Rise

The adoption of modular and prefabricated building methods in the U.S. has climbed steadily, driven by a combination of market forces and technological advancements. Developers are attracted by the promise of shortened construction schedules (factory-built modules can be produced in parallel while sitework is underway) and potentially lower overall costs. Contractors see benefits in safer, controlled manufacturing environments and reduced on-site labor needs. And amid skilled labor shortages and housing demand, policymakers are eyeing modular construction as a way to boost productivity in the construction sector.

Recent industry data illustrates this growth. According to the Modular Building Institute (MBI), modular construction accounted for 6.64% of new construction starts in 2023, up from just 2.14% in 2015. In dollar terms, the modular sector’s annual project value in North America quadrupled over that period (from about $3.7 billion to $14.6 billion). Market projections remain optimistic: one analysis forecasts the U.S. modular construction market will expand at nearly 8% annually, reaching around $19.1 billion by 2030. While modular building still represents a single-digit percentage of all construction, its share is expected to climb as more owners and jurisdictions embrace offsite methods.

This growth is evident in real-world examples. In the past decade, modular construction has been used for everything from low-rise homes and schools to mid-rise apartments and hotels. Notably, high-profile projects have tested the limits of modular technology – for instance, a 25-story Marriott AC hotel in New York City was assembled in 2022 from 168 factory-finished modules, becoming one of the world’s tallest modular buildings. Internationally, modular high-rises have reached 40+ stories, such as the 43-story twin towers at 101 George Street in the UK. These achievements are boosting confidence in offsite construction and proving that even complex, large-scale structures can be built modularly.

Key drivers behind this trend include speed and efficiency gains, improved quality control, and sustainability benefits. Because modules are built in controlled factory settings, weather delays are minimized and materials are used more efficiently, reducing waste. Modular projects often realize time savings of 30–50% compared to traditional builds, as site preparation and module fabrication occur concurrently. Consistent factory production also enhances quality and precision – each module undergoes inspection before leaving the plant, and tight tolerances are maintained by automated processes. From a sustainability perspective, modular construction can reduce material waste and even enable future disassembly or reuse of modules, aligning with circular economy principles. All these benefits, coupled with emerging digital design tools and DfMA methodologies, have set the stage for modular construction to flourish.

However, alongside the opportunities come modular design challenges that must be addressed through sound engineering. The next sections delve into those challenges and the strategies structural engineers are using to solve them.

Structural Engineering Challenges in Offsite Construction

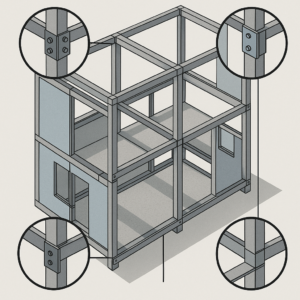

3D Cutaway of a Modular Building with Connection Callouts.

Designing a building composed of factory-made modules presents unique structural engineering challenges. Unlike a monolithic site-built structure, a modular building is essentially an assembly of many structural engineering prefab components that must act together as a single stable structure. Below are some of the key challenges (and solutions) that engineers encounter in offsite construction:

- Module Connections and Structural Continuity: Perhaps the biggest challenge is ensuring strong connections between modules. Structural elements like beams, columns, and diaphragms are segmented at module boundaries, so engineers must design connection details that transfer gravity loads and lateral forces across these joints. Achieving continuity of floor plates and alignment of vertical load paths requires careful detailing – often using steel brackets, bolted plates, or weldments at the module corners and along mating faces. These prefab structure connections need to safely carry shear and moment between modules while accommodating any fabrication tolerances. For multi-story modular buildings, connection design becomes even more critical as cumulative loads increase with height. Solution: Engineers are employing bespoke inter-module connectors (e.g. threaded rods, splice plates, or sliding connectors) that can be quickly installed during stacking. Many modular designs incorporate an internal steel frame at the module corners which provides predefined connection points for bolting modules together. Rigorous analysis and physical testing of connection assemblies are often done to validate their performance under gravity, wind, and seismic loads.

- Lateral Stability and Load Distribution: In conventional construction, continuous braced frames or shear walls might span multiple floors; in modular, the lateral force-resisting system can be more segmented. Each module may include shear walls or cross-bracing panels that must link up with those in adjacent modules to create a continuous lateral system. Lateral loads (from wind or earthquakes) therefore require special attention in modular design. Engineers must decide whether each module will handle lateral forces independently or if the building will rely on separate structural elements (such as a site-built core or frame) to resist lateral loads. Solution: For low- and mid-rise modular buildings, a common approach is to integrate shear walls or braced frames within the module walls and align them vertically through the stack. For example, in a New York modular apartment project, cross-strap braced frames were placed inside module walls, and modules were stacked with a 2-inch gap between them to allow for connections and construction tolerances. In taller modular structures, often a hybrid system is used: modules handle gravity loads, but a separate on-site steel or concrete core provides lateral stability. Engineers coordinate the structural integration so that the modules are tied into the core at each floor, combining the efficiency of modular gravity framing with the robustness of a traditional lateral system.

- Alignment and Tolerances: Because modules are built separately and then assembled, even small dimensional discrepancies can accumulate and pose problems during construction. Unlike stick-built construction where minor on-site adjustments are possible, modular projects demand a high degree of precision. For instance, if a module is even 1/4 inch too wide, four modules next to each other could end up 1 inch misaligned – a potentially serious error in a tight structural layout. Therefore, controlling fabrication tolerances and planning for fit-up is a major challenge. Solution: Engineers and fabricators employ Building Information Modeling (BIM) to model each module to exact dimensions and detect interference or tolerance issues virtually before fabrication. Connection details are designed with slotted holes or shim plates to allow for minor adjustments during assembly. As one modular project architect noted, “It’s critical that the project is modeled to ensure dimensional accuracy… if a module is built an extra 1/4″ wide and there are four modules next to each other, that can build to a 1-inch error.” This underscores why careful coordination and quality control are essential. Many modular builders also adhere to strict manufacturing standards (such as ISO quality programs) to ensure each module is produced within acceptable tolerances.

- Design Flexibility vs. Repetition: Modular construction tends toward repetitive unit designs (for efficiency), which can clash with architectural ambitions for variation. Structural layouts may be constrained by the need to align module walls and columns directly above one another for stacking. Large open spaces or irregular geometry can be difficult to achieve when working within the fixed dimensions of modules and their supporting frames. Solution: Early collaboration between architects and structural engineers is key to balancing creativity with modular feasibility. Often, the building is planned on a grid that suits standard module sizes (e.g. width and length that fit trucking limits) and the structural grid of columns or load-bearing walls repeats consistently. To introduce variety, designers might use non-structural façades or post-assembly modifications. But fundamentally, design for modular means embracing a kit-of-parts mentality – leveraging repetition and symmetry. Where unique features are necessary (such as cantilevers, atriums, or step-backs in the massing), engineers sometimes design a podium or frame to support those elements conventionally, and place modules atop or within that framework for the more regular portions. The mantra is DfMA: Design for Manufacture and Assembly – which means making early design decisions that simplify fabrication and erection without stifling the overall building function. (We will explore DfMA in more detail below.)

- MEP Integration and Fire/Ratings: Although primarily an architectural and systems concern, it bears noting that the structural design must accommodate mechanical/electrical/plumbing (MEP) routes and fire-separation requirements in a modular building. Each module is often a nearly complete section of a building (with plumbing lines, wiring, finishes installed), so structural elements cannot intrude on critical MEP space. Also, where modules join, there may be double walls/floors (one per module) which help with fire and acoustic separation but also add weight and thickness that the structural engineer must account for. Solution: The structural frame is coordinated with MEP openings from the outset. Floors and ceilings might have pre-engineered penetrations for ducts/pipes that align when modules are set. Double-stud party walls between modules can be utilized for running vertical utilities in the gap, but engineers ensure these walls still meet structural and fire code needs. Advanced projects use integrated design models (structural + MEP) to avoid clashes. As for fire protection, modular units are typically designed to the same fire-resistance standards as conventional construction; each module’s floor and walls can form effective fire compartments. The engineer might work with the manufacturer to detail fire-safe connections (using intumescent coatings or fire-stop materials at module joints) so that the assembled building meets code. While MEP and fire considerations extend beyond pure structural issues, they influence structural layouts (e.g. where beams go, where extra drywall or concrete topping is needed), making close interdisciplinary coordination vital in modular projects.

In summary, structural engineering for prefab construction requires a holistic mindset. Challenges like inter-module connections, stability, precision, and integration demand that engineers think beyond designing a static building – they must design a product that can be manufactured, transported, and assembled efficiently. Next, we examine how material choices play into these considerations.

Material Considerations: Steel, Concrete, Timber, and Hybrid Systems

One of the early decisions in a modular project is selecting the structural material for the modules. Different materials – steel, concrete, wood, or hybrids – each have advantages and limitations in offsite construction. The choice affects module weight, spanning capability, fire rating, and even feasible building height. Current industry usage is fairly evenly split between wood and steel framing for modular units, with concrete a smaller third category. According to MBI’s annual report, about 50% of North American modular projects use wood framing, ~43% use steel framing, and ~7% use concrete as the primary structural material. Let’s look at each in turn:

- Wood Modules (Timber): Wood-framed modular units are common for low- and mid-rise buildings such as single-family homes, apartments up to 4–5 stories, and classrooms. Wood offers the benefit of being lightweight and familiar – many modular manufacturers use light wood studs and trusses similar to conventional stick-built construction, but assemble them into modules in the factory. Offsite construction with wood can yield high quality, as cuts and nailing are done with precision jigs. The material is also cost-effective and has natural thermal insulation benefits. However, wood modules are typically limited in building height and span: most building codes cap wood-frame structures at a certain number of stories (often 4-5 stories for Type V construction, or up to 6 with podiums). Structural engineers must pay attention to cumulative vertical shortening (wood shrinkage) in stacked wood modules, and ensure robust detailing for lateral loads since light-frame walls may be more flexible. Fire protection is another consideration – modular units often use fire-rated sheathing and drywall to meet code. Despite these challenges, timber modular systems have seen success in multifamily housing and smaller commercial buildings, and there is growing interest in mass timber modules (using CLT panels and glulam beams) for sustainable mid-rise projects.

- Steel Modules: Steel-framed modules are prevalent for taller modular buildings and where high strength is needed in a compact profile. A steel modular frame typically consists of steel columns (often hollow structural sections) at the corners and steel beams or cold-formed steel joists for floors and roof of the module. Steel’s strength allows modules to carry heavy loads and span reasonable distances with less bulk, which helps maximize usable space inside the module. Steel modules can also be stacked higher – modular high-rises in the 10- to 40-story range have been achieved using steel systemsmodular.org. Engineers appreciate that steel fabrication can be very precise, and connections can be welded or bolted for high rigidity. However, steel modules tend to be heavier than wood, requiring sturdy foundations and consideration of transport weight limits. They also conduct heat readily, so thermal bridging must be addressed in design. Many steel modular buildings use a concrete or composite floor slab within the steel frame to control vibrations and add mass. The hybrid steel module approach (steel frame + concrete deck) can provide excellent structural performance but does add to factory complexity. Overall, steel is often the material of choice for prefabricated construction when aiming for longer spans (e.g. open-plan offices or hotels) or greater height.

- Concrete Modules: Less common but notable are precast concrete modular units. These are essentially three-dimensional concrete boxes (or volumetric concrete modules) cast in a factory, transported to site, and stacked. Concrete modules might be used for highly repetitive cell-like structures – for example, hotels, dormitories, or even prisons – where each module can be a rigid room cell. The advantages of concrete are its solidity, fire resistance, and sound insulation; a concrete module can be very durable and require minimal additional finishing. Structurally, a concrete module’s walls and slab act as a monolithic shell, which can be very strong. The challenges lie in the weight and manufacturing: concrete modules are extremely heavy, often requiring special transport equipment and large cranes. The module size may be limited by what can be lifted and trucked. Additionally, precise casting of connection inserts and ensuring alignment during assembly requires skill. From an engineering standpoint, concrete modules may need post-tensioning or reinforcement detailing that accounts for handling stresses (to avoid cracking during lifts). Despite lower market share, some innovative projects have successfully used concrete modules – for instance, student housing blocks where each dorm room is a precast module fitted out offsite and simply craned into a structural frame on site. Increasingly, hybrid systems appear where concrete floors or cores are combined with steel or wood modules to leverage the benefits of each.

- Hybrid and Novel Systems: The modular approach encourages thinking in terms of systems. Many projects end up hybrid in material: a common mix is a steel chassis with wood infill framing, marrying steel’s strength with wood’s cost and weight advantages. Another hybrid strategy is using a site-built concrete podium or core (for parking, stairs, elevators, etc.) and placing wood or steel modules on/around it for the occupiable floors – this is seen in many modular multifamily developments. Engineers are also exploring mass timber modular concepts, where a CLT floor slab and walls form the module structure, to create low-carbon modular buildings. Each material choice influences the structural design and detailing: for example, steel modules might rely on welded corner connections, wood modules might use nailed or plated connections, and concrete modules might have cast-in inserts that get bolted. Regardless of the material, all modules must be designed to meet the same performance criteria (strength, serviceability, fire, etc.) as any building. Often, the selection comes down to project requirements: structural engineering prefab solutions are tailored, whether it’s a light wood frame for a quick affordable housing project or an all-steel module for a high-end high-rise. The good news is that modular construction is material-agnostic – offsite fabrication techniques can be applied to a wide range of structural systems as long as the design is modular-friendly.

Structural Integration of Modules with Foundations and On-Site Structures

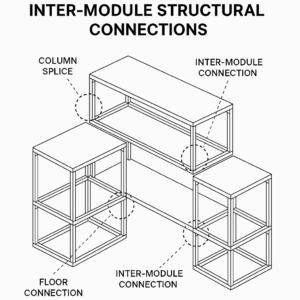

Inter-Module Structural Connections

A successful modular project doesn’t end with the modules themselves – structural integration at the job site is a critical phase. This includes how modules attach to the foundation and how they interface with any conventionally-built elements (such as podiums, cores, or additional floors). Structural engineers must ensure that when the modules are set in place, they form a continuous load path from roof to foundation, just as in any building.

Module-to-foundation connections: Typically, modular units arrive on site and are placed by crane onto a prepared foundation or podium. The interface might be a series of anchor bolts, plates, or welded connectors that tie the module’s base frame to the foundation. One common method is to embed steel plates or bolts in the foundation at the locations corresponding to the module corner columns or perimeter frame. As each module is lowered, crews make the connection – for example, by bolting the module’s steel chassis to the embedded plates or by welding outriggers from the module to the anchors. These connections must be designed to resist all support reactions from the module (gravity loads, plus any uplift or shear from wind/seismic). They also need to allow for tolerances in placement; often slots or oversized holes are provided to accommodate slight misalignments, which are then shimmed and grouted after positioning. The goal is a secure, level interface that effectively makes the module part of the foundation system. Engineers often design a leveling mechanism (like adjustable screws or shims under module corners) to get each unit perfectly level and aligned, which is crucial before stacking additional modules on top.

Inter-module connections: As discussed earlier, modules are connected to one another both vertically (stacking) and horizontally (side-by-side). Vertical connections usually occur at the corners – for instance, a vertical rod or pin may pass through aligned holes in the corner posts of modules on top of each other, clamping them together. Alternatively, bolted flange plates or even field welding can be used at the module interface. The objective is to transfer the weight of upper modules down through lower modules and into the foundation without excessive differential movement. Horizontal connections (between adjacent modules on the same level) tie the modules together to act as a unit for lateral loads and to prevent gaps. These might be accomplished with plates that bolt across the module boundary in the floor or ceiling space, or by proprietary clip systems. Structural integration design considers the sequence of assembly too: modules should be able to be connected in the order they are set. For example, if interior modules need to be bolted, there must be access either through pre-cut openings or from above before the next module is placed. Engineers plan the connection and assembly sequence hand-in-hand to avoid scenarios where a connection is impossible to reach or tighten.

Integration with site-built structures: Many modular buildings are not 100% modular; they might have a traditionally constructed element such as a first-floor podium (for retail or parking) or a central elevator core/stair shaft for lateral stability. Integrating modules with these components is another structural challenge. The junction could occur at a podium top (modules start at the second floor), or along the sides where modules abut a stair or elevator shaft. In each case, the engineer must detail connections that allow the modular units to attach to the conventional structure in a way that transfers forces but also accounts for any differences in stiffness or movement. For instance, a concrete core is very stiff, while modular frames might be a bit more flexible – connections might use slide bearings or gaps to allow the modular portion to sway slightly without inducing too much force into the core, until a certain limit where a stopper engages. Conversely, if the core is carrying lateral loads for the whole building, the modules must be securely tied at each floor level to the core so that wind forces in the modular frames are delivered into the core walls. Achieving this often involves embedded plates in the concrete core that align with module floor beams or columns, where bolts or welds can fuse the systems together. Coordination is key: the tolerances for the core construction must match the module placement so those connections line up correctly. It’s common to survey and adjust as needed so that when the module is craned into place, the attachment points match within allowable tolerance.

Foundation design considerations: From a foundation perspective, supporting a modular building is not fundamentally different from a traditional building of the same material and weight. The loads (dead, live, seismic, etc.) are calculated per code and the foundations (spread footings, mats, piers, etc.) are designed accordingly. One thing to note is that modular construction can sometimes lead to higher point loads at the module stacking points (since the module corner columns might concentrate the load), as opposed to distributed wall loads in some conventional buildings. Thus, you might see foundations under each stacking column or a tie-beam grid to distribute loads. Additionally, because modules arrive nearly complete (with finishes, etc.), the foundation must be extremely level to avoid any shimming that could cause uneven support. Engineers often specify tighter flatness criteria for modular foundations. If a podium slab is out of level, it can be very challenging to set modules plumb. Finally, when modules are installed, the structure is essentially complete far quicker than usual, so the foundation will experience full load sooner – meaning any time-dependent soil settlement needs to be understood upfront (to avoid post-construction settlement issues).

Overall, integrating modules with the foundation and any on-site construction demands the same rigor as designing the modules themselves. A modular building should behave as a unified structure once assembled, and it’s the engineer’s responsibility to ensure that all the seams between modules – and between modules and foundation – are effectively “stitched” together to achieve that unity.

Embracing DfMA: Design for Manufacture and Assembly in Modular Design

Successful modular projects often cite Design for Manufacture and Assembly (DfMA) as a guiding principle. DfMA is more than a buzzword – it’s a methodology that asks designers to consider how a building will be fabricated and put together from the very start of the design process. In the context of modular construction, DfMA means structuring the design so that it is optimized for factory production and on-site assembly. This approach has significant structural implications.

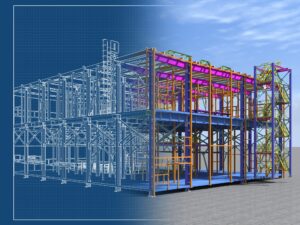

Front-loaded design and collaboration: In traditional construction, design development can be somewhat linear and iterative, and certain detailed decisions can be postponed until later phases or even adjusted during construction. Modular flips that script. Because modules are built offsite on a tight fabrication schedule, the design (including structural details) must be essentially complete and coordinated before fabrication begins. Architects, structural engineers, MEP engineers, and the modular manufacturer’s engineers all need to collaborate early to lock in a design that can be built as repeated modules. As one industry source notes, while the site’s foundation and utilities are being built, the modules are simultaneously being fabricated in the factory – leaving little room for changes mid-stream. This concurrent timeline requires a fundamentally different design process: more up-front coordination, earlier approvals of drawings, and often a digital workflow (using BIM or similar tools) to integrate all components. Engineers may find themselves working closely with fabrication specialists to adjust connection details or component sizes to fit manufacturing capabilities (for example, choosing a beam size that the factory’s machines can easily handle, or splitting a heavy assembly into two lighter ones to suit the production line). DfMA in structural design means being conscious of ease of fabrication (simpler, repeatable connections; standard member sizes; modular jigs) and ease of assembly (accessible bolted joints, self-aligning features) from day one.

Standardization and modularization: At the heart of DfMA is the idea of standardizing components to reap efficiency. For modular buildings, this translates to re-using a set of standard module types throughout the project whenever possible. From a structural perspective, that might mean repeating the same beam layouts, column locations, and connection details in dozens of modules. This repetition allows the manufacturer to refine the process and ensures each subsequent module is produced with greater precision and speed. Engineers adopting DfMA might design a structural “platform” – essentially a template structural module – that can be used in multiple configurations (a concept borrowed from product manufacturing). For example, a platform could be a steel frame module that supports either a single hotel room or, when mirrored, a double unit; having one structural design that covers multiple unit layouts reduces complexity. Standardization also extends to things like connection hardware: using the same type of bolt, bracket or weld detail throughout the building so that assembly crews become experts at that one detail. The DfMA mantra is “avoid reinventing the wheel for each module.” Instead, design a few key parts and repeat them. This does not mean the entire building is monotonous – clever architectural planning can yield variety using a limited kit-of-parts – but it means the underlying structural skeleton has consistency. The benefit is not only efficiency but also reliability: every repetition is a chance to improve quality, and the structural performance becomes very predictable. As a bonus, bulk ordering standardized structural components can lower material costs.

Incorporating manufacturing constraints: A key aspect of design for manufacture is understanding the constraints of the fabrication process and equipment. For instance, if modules are built indoors, there may be limits on how tall or wide a module can be maneuvered inside the factory bays. The crane or gantry in the plant might limit module weight. The engineering team must communicate with the manufacturer: e.g., what are the maximum lengths of steel the factory can weld without distortion? What fastening methods (welding, bolting, nailing) does the factory prefer for speed and safety? DfMA-oriented structural engineers will adjust their designs accordingly – maybe using bolted splice connections if the transport length must be shorter than the desired span, or designing two smaller trusses that can be bolted together if a full-span truss won’t fit in the paint booth. They also consider the assembly sequence: each module’s structure might need temporary stiffening or attachment points to facilitate lifting and joining. For example, engineers might add lifting lugs or brackets to the module design (which are later removed or concealed) to allow cranes to pick the module without damaging it. All these details reflect a DfMA mindset, ensuring that the structure is not only strong in its final state but also robust and convenient during fabrication and assembly.

BIM and digital integration: Modern modular projects heavily leverage Building Information Modeling and other digital tools as part of DfMA. A shared BIM model allows the entire team to coordinate structural, architectural, and MEP systems in a virtual space, catching conflicts early – which is essential when changes later would be costly or impossible. Some modular manufacturers use parametric design software to automate certain aspects of module design, allowing quick iteration to find an optimal structural solution that balances weight, cost, and manufacturability. There’s also the concept of digital twins – creating a detailed digital replica of each module and even simulating the factory assembly steps. This can help identify inefficiencies or risks (say, a bolt that is hard for a worker to reach during assembly). For structural components, BIM ensures that things like connection plates align perfectly between modules and that bolt holes will match up. Many factories now use CNC machines and automated cutters driven directly by the design model, which means the accuracy of the engineer’s model translates to accuracy in the real part. Thus, structural engineers are increasingly expected to be fluent in these digital tools and to produce shop-drawing-level detail in their design models as part of the DfMA process.

In essence, DfMA encourages structural engineers to think like manufacturers: consider how every beam, column, and connection will be made and assembled, and streamline those steps through smart design. This approach reduces waste (in both time and material) and helps ensure that the modular structure comes together smoothly on site. As one modular construction team put it, “Modules must be designed with precision to align perfectly when transported and assembled on-site, accounting for constraints like transportation dimensions and structural reinforcement for lifting.” DfMA provides the framework to achieve that precision and reliability.

3D BIM Model Screenshot of Modular Building

Transportation, Lifting, and Tolerance: Logistics Impact on Structural Design

One of the defining differences between offsite construction and traditional building methods is the need to transport completed modules from the factory to the site and then lift them into place. These logistical steps impose additional design criteria on the structural engineer. A module isn’t just a part of a building; for a while, it’s also a self-contained shipping container and a crane load. Understanding and designing for these conditions is crucial to avoid damage and ensure safety. Here are key considerations regarding transportation, lifting, and tolerances:

- Shipping Size and Weight Limitations: Modular units must conform to highway regulations for transport. In the U.S., this typically means module dimensions are constrained to roughly 8.5 feet wide (up to ~16 feet with special permits), about 60–70 feet long at most for a single transportable unit, and a height that can pass under bridges (often around 11 to 13.5 feet including the trailer). These limits directly affect structural design – for example, a module’s width might be capped at ~12 to 14 feet for practical transport, influencing the room sizes and structural span. If a wider space is needed, it must be achieved by joining modules side-by-side on site. Engineers must ensure that the module can be safely lifted onto a truck and will not overstress under its own weight plus road vibrations. Weight is also a concern: overly heavy modules may require escort vehicles or specialized transport, so the structural system should be efficient. For instance, using lightweight materials (like cold-formed steel or engineered wood) can help keep module weight down. In some cases, non-structural elements are shipped separately if they risk making the module too heavy or wide (e.g. exterior facades or large overhangs might be attached on site instead). By designing within transport limits, engineers ensure the modules can actually reach the site – this is a clear example of DfMA in practice (designing for manufacture and delivery).

- Structural Reinforcement for Lifting and Handling: A module experiences different forces during lifting and moving than it does in its final installed state. When a crane picks up a module (usually by four lift points at the top or bottom), the module might bend or rack if not stiff enough. Often, the most significant loads a module faces are during craning or transport, not in-service. For example, as one project engineer noted, if modular boxes are not rigid enough, their interior finishes can crack during lifting or transport vibrations. Engineers must analyze the module for these temporary load cases: dynamic lifting forces, potential uneven support (if a module is lifted not perfectly level), wind loads on the module during transport, and even acceleration/braking forces of the truck. It may be necessary to design additional reinforcement – such as extra steel members or temporary strongbacks – to keep the module square and intact until it’s placed. Many steel modules include a rigid frame precisely to handle lifting; wood modules might have sacrificial bracing that is installed for transport and removed after installation. The connection points for lifting (lifting lugs, rings, or slots for slings) have to be integrated into the structural design as well, often requiring local reinforcement to prevent tear-out. Crane lifting also means the module might be picked from the top or from the bottom. Top-picking (using attachments on the roof of the module) puts the module in tension like a hanging basket, whereas bottom-picking (using a spreader bar and lifting from below the module) puts it in bending. The engineer ensures the module’s structure can handle both scenarios if needed, or specifies the method of lifting in the plans so that the contractor knows how to rig the module correctly. In short, the module must be structurally sound as a free-standing unit during handling – an engineering consideration outside the scope of normal building design.

- Tolerance Buildup and Dimensional Control: We discussed earlier the importance of fabrication accuracy for module alignment. During transport and lifting, additional tolerances come into play. A steel module, for instance, might thermally expand or contract a bit as it goes from factory to outdoor site. Or a long module might experience slight deflection in the middle when lifted, meaning the ends could be a fraction of an inch closer together until it’s set down. Cumulative tolerances – from fabrication, transport-induced deflection, and setting placement – all need to be managed so that modules fit together correctly. Engineers address this by specifying tolerance requirements and by designing connections that are somewhat forgiving. Typically, a gap (often 1 to 2 inches) is left between modules when installed. This gap allows for minor misalignments and is later covered or finished (for example, with trim or a shim space that is closed up). The 2-inch gap used in the NYC “Stack” apartments was specifically to allow for tolerance and to make space for bolting the modules together. Additionally, guides or alignment features can be built into modules – for example, funnel-shaped receivers that help pull modules into the right position as they come together. The structural engineer might incorporate shear keys or locator pins at module interfaces which ensure that as soon as one module sits on another, it’s practically locked into the correct position. During installation, surveyors will check each module placement, and if something is off by more than the allowed tolerance, the crew can adjust (perhaps by using jacks to push modules into alignment or by shimming). The structural design should tolerate these minor adjustments without damage. It’s a delicate balance: connections need to be snug enough to transfer load but flexible enough to adjust during erection.

- Environmental and Dynamic Effects: Transporting a module on public roads means it could be subjected to wind gusts, vibrations from rough pavement, and even minor impacts or sudden stops. While these are not typically extreme loads, they can be significant for finishes and cladding attached to the module. From a structural standpoint, the primary concern is the module’s durability under repeated vibration – welds and connections should not loosen. If a module includes brittle materials (like masonry veneer or brittle finishes), the structural engineer might suggest they be installed on-site instead of in-factory, to avoid cracking in transit. Also, if modules are stored on site before placement, they must either remain on their trailers or be supported in a way that doesn’t induce unintended stresses (e.g., sitting a module on an uneven surface that twists it). Engineers may specify temporary supports or the order in which modules can be stacked to avoid overstressing a partially completed structure. Lifting operations also have environmental considerations – for example, if high winds arise, crane picks may be postponed; engineers often specify allowable weather conditions for lifting large modules (since a swinging module in high wind can be dangerous). While these logistical issues are often handled by contractors means and methods, the engineer’s input is crucial in planning for them and ensuring the structural design is robust enough to handle the journey from factory to final position.

In summary, the path a module takes – from factory floor, onto a truck, up by crane, and finally into the building – is full of potential pitfalls that the structural design must preemptively address. This is a differentiator of prefab structure engineering: the need to consider non-traditional load cases and movements. By designing with transportation, lifting, and tolerance in mind, engineers help ensure that a module that leaves the factory is the same module that arrives and fits perfectly on site, with no surprises in between.

U.S. Codes and Standards for Modular Construction

Structural engineers working on modular projects must navigate the same rigorous building codes as any conventional project – with some additional layers of review to account for offsite fabrication. In the United States, modular buildings are generally required to meet the exact same structural codes and standards as site-built structures. However, because modules are constructed in a factory (often in a different state or jurisdiction than the final site), there are special procedures and evolving standards to ensure code compliance and safety. Below is an overview of the key codes, standards, and regulatory considerations relevant to modular construction:

- International Building Code (IBC) – Primary Building Code: The IBC (and its state or local adaptations) is the foundational code that modular buildings must comply with, just as with any building. All structural provisions of the IBC and referenced standards (such as ASCE 7 for loads, ACI 318 for concrete, AISC 360 for steel, AWC NDS for wood design, etc.) apply to modular construction. For example, a modular apartment building must satisfy the same wind and seismic design requirements per ASCE 7 as a traditional build. MBI emphasizes that off-site construction uses the same materials and is designed to the same codes and standards as conventional construction. There is no special leniency in structural performance criteria – modular is just a delivery method. That said, one code-related benefit of modular is that each module can be viewed as a separate small structure for certain evaluations (like fire containment), but it ultimately has to perform as part of the whole building in an event like an earthquake.

- State and Local Modular Programs: Many U.S. states have established specific programs or guidelines for modular (or “industrialized”) buildings. Typically, a state agency or third-party evaluator will review the modular plans and inspect the factory production to ensure compliance with the state’s adopted building code. For instance, California’s HCD (Housing and Community Development) department oversees factory-built housing and requires that modular units destined for CA are inspected and certified in the factory. Other states have similar setups, often issuing a label or stamp for each module that certifies it meets code. The reason is to streamline on-site approvals – local inspectors may not inspect inside factory-built modules (since that work was done out of their jurisdiction), so the state-level approval ensures the module was built to code. However, navigating these varying state requirements can be challenging for modular firms operating nationally. Differences in state or local codes (for example, seismic detailing requirements in California vs. less stringent requirements in another state) must be reconciled in design. Failure to account for a specific local provision can lead to delays or retrofits. For example: one modular company encountered delays when California officials found that their factory-built modules didn’t meet a particular local fire safety provision. The lesson is clear – early engagement with the relevant authorities and possibly hiring code consultants is wise when doing modular projects across different regions.

- ICC Off-Site Construction Standards (ICC 1200 & 1205): Recognizing the need for standardized guidelines, the International Code Council (ICC) – in collaboration with the Modular Building Institute – has published new standards for off-site and modular construction. ICC 1200-2021, Standard for Off-Site Construction: Planning, Design, Fabrication, and Assembly, and ICC 1205-2021, Standard for Off-Site Construction: Inspection and Regulatory Compliance, were developed to supplement existing codes. These ANSI standards serve as an authoritative reference specifically addressing modular project considerations. For structural engineers, ICC 1200 provides guidance on how to approach design and documentation for modules (e.g., requiring that transport and lifting loads be considered in the design, and detailing how connections should be documented). ICC 1205 deals with the inspection process, helping jurisdictions understand how to approve modular projects (e.g., recommending third-party inspection protocols, outlining the role of the factory’s quality control versus site inspections). While these standards are relatively new and may be adopted on a voluntary basis or integrated into building codes over time, they indicate a trend toward formalizing modular construction practices. By following ICC 1200/1205, engineers and builders can align with industry best practices and potentially smooth out the approval process with authorities, since these standards fill in the gaps not explicitly covered in the IBC. In essence, they aim to ensure modular construction meets or exceeds the intent of the code, even accounting for its offsite nature.

- Regulatory Hurdles and Approvals: Despite code compliance being mandatory, the modular approach can introduce regulatory complexity. Codes and standards sometimes lag behind innovation – a fact that can lead to uncertainty in securing permits. For instance, an engineer might have to convince a local code official that a proposed inter-module connection meets the intent of code even if the code doesn’t explicitly describe modular connections. Some code provisions, like special inspection requirements, must be adapted for factory work (third-party inspectors act on behalf of local officials in the plant). Engineers should be prepared to provide detailed calculations, test results, and perhaps rational equivalency arguments for novel design aspects. Working closely with building officials and educating them on the modular system goes a long way. Fortunately, the landscape is improving as modular becomes more common: more jurisdictions are familiar with modular projects, and resources like the ICC standards and MBI guidelines are helping create a common understanding. Still, it’s prudent to build in extra time for plan checks and to involve the authority having jurisdiction early in the design process.

- Material Codes and Listings: Each structural material used in a modular building must comply with its respective standard, and often components need to be listed or approved for use. For example, if a proprietary connection device is used between modules, it might need an evaluation report (such as an ICC-ES report) to satisfy code officials of its strength. Similarly, welds in structural steel modules are performed in the factory, so the fabrication facility usually needs to be certified (e.g., AWS or AISC fabrication certifications) to ensure quality equivalent to field welding under inspection. Modular wood components might be prefabricated trusses, which carry ANSI/TPI approvals. The structural engineer should specify code-compliant materials (no different than normal practice) and work with manufacturers who maintain the necessary certifications. Some jurisdictions also require the modular manufacturer to be licensed or approved as a “factory manufacturer” with periodic audits.

In summary, “modular building code” compliance is fundamentally about meeting the standard building code requirements, but executed through a slightly different process. Structural engineers must design to the same safety factors and load combinations; what changes is how and where the inspection and verification happen. By understanding the regulatory framework – from the IBC to state programs and new ICC offsite standards – engineers can ensure their modular designs are not only safe and efficient, but also approvable. As modular construction becomes more prevalent, codes are evolving to keep pace, and engineers who stay abreast of these developments will be well-positioned to lead in this modular future.

Conclusion

The rise of modular and offsite construction represents a significant shift in the building industry, and structural engineers play a pivotal role in its success. Modular construction marries the worlds of manufacturing and architecture – buildings are becoming products, with all the efficiencies and challenges that implies. We’ve explored how the approach is gaining ground in the U.S., fueled by needs for speed, quality, and productivity. We’ve also delved into the nitty-gritty structural considerations: ensuring strong connections between modules, devising lateral systems that keep buildings safe, maintaining tight tolerances, and choosing the right materials for the job. Concepts like Design for Manufacture and Assembly (DfMA) and careful logistics planning have emerged as essential tools for engineers to master in this realm.

Ultimately, the future is modular not just because it can make construction faster or cheaper, but because it challenges us to improve how we design and build. By thinking holistically about the entire lifecycle of a structure – from factory floor to final bolt – engineers are innovating new solutions that can raise construction to a new level of precision. Hybrid materials, advanced digital models, and updated codes are all converging to make prefab projects more viable than ever. And while challenges remain (as with any innovation, from ensuring code officials are onboard to fine-tuning connection technologies), each successful project paves the way for the next.

For structural engineers, engaging with modular construction is an opportunity to expand one’s skill set and collaborate in new ways with architects and manufacturers. The projects demand creativity (to solve unique design constraints) and pragmatism (to simplify and standardize for production). As we look ahead, one can envision modular techniques being applied to an even wider range of structures – from high-rise offices to infrastructure – supported by a robust framework of codes and best practices.

In the U.S., as in many parts of the world, the construction industry is at an inflection point. Offsite fabrication and prefabricated building assemblies are poised to help meet pressing needs: housing attainable housing, rapid post-disaster construction, greener building processes, and more. Structural engineers, by addressing the considerations outlined here – from modular design challenges to on-site integration – are turning the promise of modular into reality. The blueprint of the future might not be a typical set of drawings at all, but a coordinated digital model feeding a factory production line. And beyond that blueprint, when those modules click into place on site with precision, we’ll know we’ve truly embraced the future of construction.

Modular construction demands precision—especially at the envelope.

At Aquinas Engineering, we specialize in structural calculations for modular façades, cladding systems, and full building envelope integration. Whether you’re working with steel, wood, or hybrid modules, our team ensures your envelope performs under code, load, and climate.

Let’s connect and simplify the complex. Contact us today.

References:

- Modular Building Institute – “2024 Annual Report: Permanent Modular Construction.” (Industry data showing modular market share growth from 2.14% in 2015 to 6.64% in 2023, with project value rising to $14.6B)modular.org.

- Grand View Research – U.S. Modular Construction Market Growth & Trends (Sep 2023). (Projection that the U.S. modular market will reach $19.17 billion by 2030, growing ~7.8% CAGR, driven by off-site adoption and labor shortage solutions)grandviewresearch.com.

- Modular Building Institute – “Key Markets and Material Usage, North America.” (Statistics on material usage in modular construction: ~50% wood framing, 42.9% steel framing, 7.1% concrete, reflecting prevalent prefab materials)modular.org.

- Structure Magazine – John R. Pasanisi, P.E., “Modular Challenges and Solutions: The Stack.” (Case study of a 7-story modular apartment in NYC; discusses 12 ft module width, 2-inch gaps for tolerance, use of steel chassis, and critical nature of transportation loads causing interior finish cracking if modules aren’t stiff)structuremag.org.

- Epstein Global – “World’s Tallest Modular Hotel – AC NoMad.” (Project insights; emphasizes need for dimensional accuracy: a 1/4″ deviation per module could result in a 1″ error over four modules, highlighting tolerance control)epsteinglobal.com.

- Volumetric Building Companies (VBC) – “What We Wish Architects Knew About Modular.” (Explains DfMA in modular construction: design is optimized for factory production and on-site assembly, accounting for transport dimensions, lifting reinforcement, and precise MEP integration)vbc.co.

- VBC – (Concurrent timelines require front-loaded design: while foundations are built on-site, modules are fabricated off-site, so architects/engineers must finalize designs much earlier than traditional projects to avoid costly changes)vbc.co.

- LinkedIn – Ali Salman, “Why Modular Manufacturers Fail…Challenges and Fixes.” (Notes that ICC introduced offsite construction standards ICC 1200-2021 & 1205-2021 as industry benchmarks for modular design and inspection, improving regulatory clarity)linkedin.com.

- Modular Building Institute – “What is Modular Construction?” (Defines modular construction as using same materials and designing to the same codes and standards as conventional construction, but in a controlled off-site environment and roughly half the time)modular.org.

- LinkedIn – Ali Salman, “Why Modular…Challenges.” (Example of code compliance challenges: Katerra’s modules faced delays when California’s state agency found non-compliance with local fire code provisions, underscoring the need to navigate differing codes)linkedin.com.

- RISA Engineering Blog – “Benefits and Challenges of Modular Construction.” (Highlights that codes and standards often lag behind innovation, creating regulatory uncertainties and the importance of ensuring prefab modules meet all code requirements for approvals)blog.risa.com.